|

Communication questions

|

|

| brittacw | Date: Monday, 26.10.2015, 18:51 | Message # 1 |

|

Private

Group: Users

Messages: 4

Status: Offline

| Hi Alexander, thanks a lot for your hard work on this program

I am new to Process Simulator, and I was wondering if it would work in my situation. I need to pass data from an OPC-DA server, which I saw is an available connection in the program. Then the simulation output must be passed to an OPC-DA client (perhaps using Modbus) which is a Siemens PLC.

Let me know if this description needs to be more specific, I have not tried implementing it with Process Simulator. Just asking if you think this would be a good use for the program.

And thanks again!

|

| |

| |

| Alexor | Date: Monday, 26.10.2015, 21:55 | Message # 2 |

|

Major general

Group: Administrators

Messages: 311

Status: Offline

| Welcome :)

I think PS is suitable for your task. Also, you may use S7IsoTCP connection to write simulation output directly to Siemens PLC S7-300/400 (S7-1200/1500 with limitations).

Try it, and if you will have any questions do not hesitate to ask.

|

| |

| |

| brittacw | Date: Wednesday, 04.11.2015, 13:01 | Message # 3 |

|

Private

Group: Users

Messages: 4

Status: Offline

| Hi Alexor, thanks for the reply.

I have had some time to work on the project. I have success in connecting a model in Mechatronics Concept Designer (MCD) with PS. However I am having trouble with the PS - PLC connection. PS is able to "see" the PLC in Connections, using the IP address of the PLC (I am using an Ethernet cable). However the connection quickly breaks due to errors if I create an Item.

Connection ´Connection 1´error. MD0.0 DWORD CLI : function refused by CPU (Unknown error)

I am very new to this topic, so I do not know how to configure the PLC connection. I have tried different data types, etc.

The goal is for example, an initial test where the position of a cube in MCD is controlled by a simple program on the PLC, such as a counter. The PLC is of the S7300/400 type.

Thanks again

|

| |

| |

| Alexor | Date: Wednesday, 04.11.2015, 17:53 | Message # 4 |

|

Major general

Group: Administrators

Messages: 311

Status: Offline

| Hi,

What Rack/Slot number do you use for connection? If PLC is S7-300, need to use 0/2.

|

| |

| |

| brittacw | Date: Wednesday, 04.11.2015, 19:27 | Message # 5 |

|

Private

Group: Users

Messages: 4

Status: Offline

| Hi Alexor,

I was using 0/0 and 0/1, thanks for the tip. The connection is now holding! I willl keep working on it further now.Added (04.11.2015, 19:27)

---------------------------------------------

By the way, I have one more problem

I am trying to install PS on a second Windows PC, but I receive the error:

"There is a problem with this Windows Installer package. A program required to install to complete could not be run. Contact your support personnel or package vendor."

Any suggestions? Thanks again

|

| |

| |

| Alexor | Date: Thursday, 05.11.2015, 17:59 | Message # 6 |

|

Major general

Group: Administrators

Messages: 311

Status: Offline

| Need Administrator rights to install program. Also try to disable UAC.

|

| |

| |

| brittacw | Date: Monday, 09.11.2015, 10:47 | Message # 7 |

|

Private

Group: Users

Messages: 4

Status: Offline

| Hi Alexor,

I can now report success! For reference if anyone is interested, I used PS with the S7IsoTCP (rack/slot 0/2) to connect to the Microbox, and the connection appears in the TIA Portal program. Then with MCD I used the OPC connection to detect the values in PS. In summary:

MCD - (OPC) - PS - (S7IsoTCP via Ethernet) - TIA Portal / Microbox

MCD & PS on one PC..................................TIA Portal on a second PC

Thanks for the helpful support!

|

| |

| |

| gstruwig | Date: Monday, 18.07.2016, 21:50 | Message # 8 |

Private

Group: Users

Messages: 3

Status: Offline

| Hi Alex,

I am trying Process Simulator for the first time today. Thank you for useful software.

I am using MQTT protocol and can send message successfully to the broker.

I am wanting to send boolean string '0' or '1' from a Sensor.discrete but message sent is 'True' or 'False'. I tried changing signalisation to 0 and 1 but this makes no difference.

How can I do this?

Thanks

|

| |

| |

| Alexor | Date: Tuesday, 19.07.2016, 08:36 | Message # 9 |

|

Major general

Group: Administrators

Messages: 311

Status: Offline

| Hi,

Signalization in Sensor.Discrete is just text messages to log/tell when the value was changed.

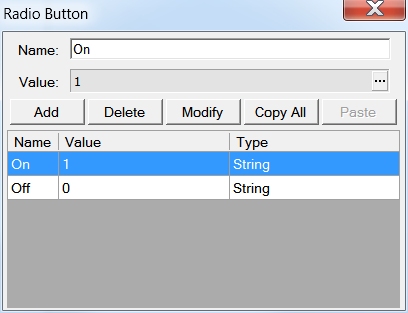

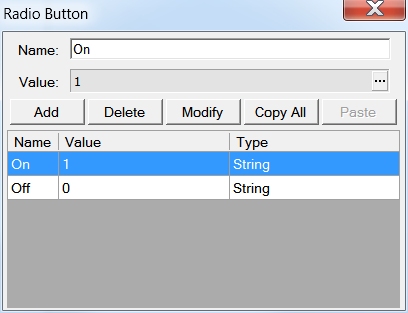

I think the simplest way for you is to use RadioButton without Sensor.Discrete. Just create MQTT Item and in “Add Panel” window choose “Communication” tab. In RadioButton setup, you can add two values, for example, “ON” – 1 and “OFF” – 0.

|

| |

| |

| gstruwig | Date: Tuesday, 19.07.2016, 15:06 | Message # 10 |

Private

Group: Users

Messages: 3

Status: Offline

| Thank you Alex, that works for me.

I am now having a similar problem sending analog value. I need to send Integer but Sensor.analog sends decimal.

It would be good if MQTT protocol not default to string but let you choose data type then then use Convert toString to send Topic. This way string could be formatted.

Maybe this is a topic for Enhancements.

Thanks

|

| |

| |

| Alexor | Date: Wednesday, 20.07.2016, 09:10 | Message # 11 |

|

Major general

Group: Administrators

Messages: 311

Status: Offline

| I will think about your idea.

If you are not afraid of a little programming work, you can use Script.CSharp for any conversion you want. For intermediate

data storing use Items of Internal connection.

For example:

Internal.A is double type value (Sensor.Analog).

MQTT.A string value you want to publish.

C# code for Script.CSharp: 'MQTT.A' = Convert.ToInt32((double)'Internal.A').ToString();

Decrease Trigger Time in Script.CSharp options to speed up conversion. Default value is 500 ms.

Tip for Boolean:

if((bool)'Internal.B')

{

'MQTT.B' = "1";

}

else

{

'MQTT.B' = "0";

}

|

| |

| |

| gstruwig | Date: Wednesday, 20.07.2016, 16:02 | Message # 12 |

Private

Group: Users

Messages: 3

Status: Offline

| Thanks Alex,

I already figured out to use the Internal connection for boolean conversion :)

I will do the same with Analog. Thank you for your help and a brilliant program.

|

| |

| |

| thalespmendes | Date: Wednesday, 15.03.2017, 16:05 | Message # 13 |

|

Private

Group: Users

Messages: 1

Status: Offline

| Hi Alexor,

I would like to know which type of communication server (OPC-UA server or OPC-DA server) the process simulator creates when establishing a S7_PLCSIM connection?

Thanks

|

| |

| |

| Alexor | Date: Thursday, 16.03.2017, 08:46 | Message # 14 |

|

Major general

Group: Administrators

Messages: 311

Status: Offline

| Hi,

Process Simulator use COM object S7ProSim for connection to Siemens S7-PLCSim.

https://alexsentcha.wordpress.com/using-s....-plcsim

PS always creates OPC-DA server for all Items, not only S7PLCSim.

|

| |

| |

| 2190326Max | Date: Tuesday, 05.03.2019, 18:23 | Message # 15 |

|

Private

Group: Users

Messages: 3

Status: Offline

| Hello, Alexander. Thank you again for the opportunity of using your work. It's powerful.

I recently started learning C# and also Modbus, but I don't have the HW, but I have the desire. I have a projects Siemens PLC our objects, on the basis of which I can do something. I've only just started, and you've come a long way.

I have a COM port Emulator, modbus slave emulator, Process Simulator (as modbus master, as I am understand) and Siemens PLCSIM as in the diagram. I was able to establish a connection between Process Simulator, COM ports and Modbus Slave emulsifier and PLCSIM. Only connection yet. What are the possible ways have Process Simulator for data transfer from the PLC to the registers Modbus slave emulator? How can I make it as close to reality as possible? Thanks

Reference on picture

https://c.radikal.ru/c38/1903/8c/bb3f34ce264b.png

|

| |

| |